Maximize cubic volume in your prefabricated steel structures by strategically deploying vertical expansion. For spaces exceeding 30 feet in height, consider selective pallet racking systems allowing individual access to each load. Bolted, not welded, connections are crucial for future adaptability and seismic compliance, a factor often neglected in initial design.

Implement a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) alongside adjustable steel shelving to optimize workflows. Aisle widths should accommodate your specific forklift turning radius, typically ranging from 10 to 13 feet for counterbalance trucks. Invest in heavy-duty wire decking; it prevents dust accumulation and improves sprinkler system coverage.

Analyze load distribution meticulously. Exceeding the permissible load per level, indicated on the racking system’s load placards, compromises structural integrity. Prioritize powder-coated finishes over painted ones for enhanced resistance to corrosion in demanding environments like warehousing refrigerated goods or storing caustic materials. Consider mobile aisle racking for a 50% reduction in floor space compared to static rack arrangements, but ensure adequate floor loading capacity before installation.

Choosing the Right Racking for Your Steel Structure

Prioritize adjustable boltless racks for industrial spaces demanding adaptability. These units offer easy reconfiguration without specialized tools, accommodating varied inventory heights. For instance, a rack with 2-inch beam adjustment intervals provides maximum vertical space utilization.

Load Capacity and Material

Calculate load requirements accurately. Light-duty units typically handle up to 500 lbs per level, ideal for retail display. Medium-duty racks support 500-1500 lbs, suiting workshops. Heavy-duty options, exceeding 1500 lbs, are best for industrial warehouses. Select steel gauge accordingly: 14-gauge steel is suitable for medium-duty, while 12-gauge or thicker is recommended for heavy-duty applications. Consider wire mesh decking for increased airflow and spill containment; solid decking offers a more robust surface for concentrated loads.

Space Optimization Strategies

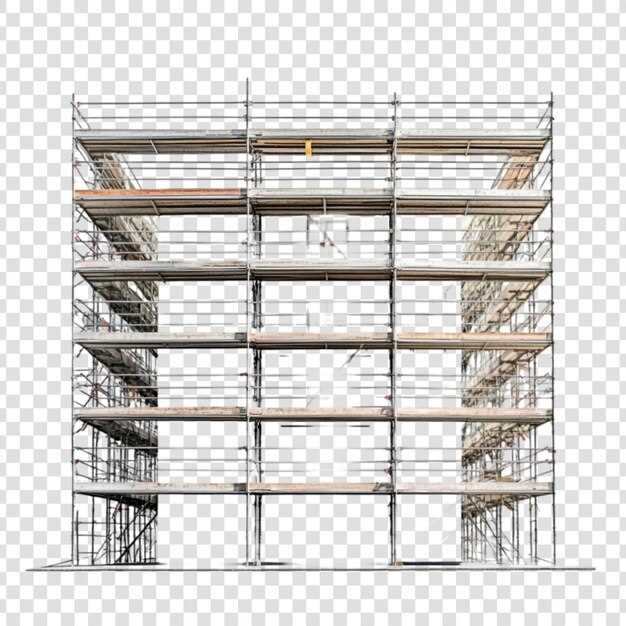

Maximize vertical areas with mezzanine-integrated frameworks. These elevated platforms double usable floor area. For narrow aisles, mobile or compact systems offer high-density arrangement, reducing aisle space by up to 50%. Pallet racks, specifically designed for forklifts, are crucial for inventory handling. When opting for cantilevered setups, ensure adequate overhead clearance to accommodate extended or oversized items such as pipes or lumber.

Installing Commercial Racking Securely

Use anchor bolts sized appropriately for the load. For concrete floors, employ wedge anchors with a minimum embedment depth of 3 inches and a pull-out strength exceeding the calculated maximum load by a factor of safety of at least 2.5. Verify the concrete’s compressive strength meets the anchor manufacturer’s specifications.

When installing on uneven floors, utilize shims beneath the vertical supports. Shims should be made of steel or a high-density polymer with a compressive strength greater than 5,000 PSI. Ensure the vertical supports are plumb within a tolerance of 1/8 inch per 10 feet of height using a precision level.

Inspect all uprights and beams for damage before installation. Replace any components exhibiting bends, dents exceeding 1/4 inch in depth, or cracked welds. Torque beam connectors to the manufacturer’s specified value using a calibrated torque wrench. Generally, this ranges from 20 to 30 ft-lbs for most common clip connections.

For pallet racks in seismic zones, implement seismic bracing following local building codes and engineering specifications. This includes diagonal bracing, base isolators, and top ties connected to the overhead structure. Consult a structural engineer to determine the correct bracing system for the installation site.

Always use safety pins or locking clips to secure beams to the uprights. Check the pins or clips engage correctly with the upright frame and are correctly aligned. The absence of these safety features compromises the integrity of the entire structure.

After assembly, conduct a load test, placing weights progressively onto the rack to a level exceeding the design capacity by 10%. Observe the structure for any signs of deflection, instability, or component failure. Record all measurements and findings.

Provide personnel training on safe loading procedures, weight distribution guidelines, and rack inspection protocols. Establish a regular inspection schedule, documenting any identified damages or hazards. Implement a system for immediate reporting and repair of compromised parts.

Organizing Your Galvanized Iron Structure Fixtures for Access

Prioritize items accessed daily within arm’s reach on center fixtures. Seldom-used items belong on higher or lower shelves. Label everything.

Inventory Management & Labeling

Use a three-zone labeling strategy: (1) Location Label (Aisle-Rack-Shelf), (2) Content Label (detailed item description), and (3) Quantity Label (current count). This system immediately tells you where to find something and its present stock. Consider QR codes linked to a digital inventory spreadsheet for real-time tracking. Aisle width should permit easy movement with common cart sizes; measure and adjust spacing accordingly.

Vertical Optimization for Industrial Shelves

Adjust fixtures to match item height, eliminating wasted airspace. Heavy items go on lower levels for stability and easier lifting. Use adjustable dividers to support smaller items, preventing tipping. Clear aisles of obstructions. Maintain a minimum of 36 inches between units for safe passage. Aisle cones, colored tape, or painted lines further define traffic areas. Consolidate similar goods within the same area. For example, group all plumbing components together, separating them from electrical supplies.

Q&A

I’m considering adding shelving to my metal building, but I’m worried about drilling into the metal. Could this damage the structure or void any warranties?

That’s a valid concern! Drilling directly into the metal framing of your building *can* create potential issues if not done correctly. It’s *extremely important* to consult the building manufacturer’s documentation regarding modifications. They often have specific guidelines on acceptable drilling locations, fastener types, and sealing procedures. Deviating from these guidelines *could* affect the structural integrity and, yes, *possibly* void the warranty. Look for shelving systems designed for metal buildings that utilize alternative mounting methods, such as clamping systems or attachment to existing framing members without requiring drilling. These are much safer options. Also, before drilling, precisely locate any wiring or pipes to prevent damage. Consider consulting a qualified contractor experienced in metal building modifications.

What type of shelving material is best for a metal building that can get quite hot in the summer and potentially have some moisture issues?

Given the potential for temperature fluctuations and humidity in a metal building, some materials are superior to others for shelving. Avoid particleboard, as it’s easily damaged by moisture. Wood shelving, while aesthetically pleasing, can warp over time with temperature swings and moisture exposure. Metal shelving (steel, stainless steel, or aluminum) is usually the preferred choice. Steel provides strength and affordability. Stainless steel is a good choice in very corrosive environments. Aluminum provides a good strength-to-weight ratio and is rust-resistant. Consider a powder-coated finish to provide an additional layer of protection against corrosion. Plastic shelving, especially high-density polyethylene (HDPE), is also a good option, as it’s resistant to moisture and some chemicals. Select the material that balances cost, strength, and resistance to environmental factors present in your building.

My metal building has limited floor space. Are there any shelving options that maximize vertical space without blocking access to other areas?

Absolutely. Vertical space utilization is key when dealing with limited floor space. Consider high-bay shelving systems if your building has sufficient ceiling height. These allow for dense storage and can be accessed with forklifts or order pickers. Mezzanine systems create an additional level of storage above the existing floor, effectively doubling your usable space. Wall-mounted shelving is another good choice as it leaves the floor clear. Cantilever shelving, which doesn’t have front vertical supports, are very appropriate for storing long items, pipes, lumber and other things where vertical uprights might get in the way.

I need to store heavy items on the shelves. What should I look for in terms of weight capacity and shelving design?

When storing heavy items, weight capacity is paramount. Carefully check the manufacturer’s specifications for the *maximum load capacity per shelf* and *the total load capacity of the shelving unit*. Distribute the weight evenly across the shelf to prevent concentrated stress. Look for shelving with reinforced shelves, such as those with wire mesh or solid steel construction. The gauge of the steel used in the shelving frame is also very relevant; a lower gauge number indicates thicker and stronger steel. Boltless shelving systems often have impressive weight capacities due to their interlocking design. Avoid shelving made from lightweight materials if heavy storage is a requirement. Before loading any shelves, double-check the weight ratings.

What are some tips for organizing the shelving in my metal building to make it easier to find and access items?

Good organization will save you considerable time and frustration. Implement a clear labeling system using large, readable labels for each shelf or storage bin. Group similar items together and create dedicated zones for different types of materials (e.g., tools, supplies, finished goods). Use clear storage containers or bins to keep smaller items contained and visible. Regularly rotate stock, placing older items at the front for easier use (first in, first out). Create an inventory system to track the location of items. Consider using color-coded labels to further categorize items. Most importantly, establish and maintain a regular cleaning and organization schedule to prevent clutter from accumulating.